HOW TO

AVOID PWHT

|

|

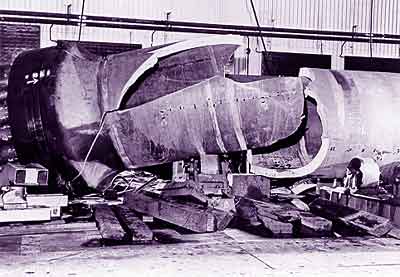

The above picture is of a new pressure vessel that failed during its hydraulic

test. The vessel had been stress relieved, but some parts of it did not

reach the required temperature and consequently did not experience adequate

tempering. This coupled with a small hydrogen crack, was sufficient

to cause catastrophic failure under test conditions. It is therefore

important when considering PWHT or its avoidance, to ensure that all possible

failure modes and their consequences are carefully considered before any action

is taken. |

|

The post weld heat treatment of welded steel fabrications

is normally carried out to reduce the risk of brittle fracture by: -

- Reducing residual Stresses. These stresses are created

when a weld cools and its contraction is restricted by the bulk of the material

surrounding it. Weld distortion occurs when these stresses exceed the

yield point. Finite element modelling of residual stresses is now possible,

so that the complete welding sequence of a joint or repair can be modelled

to predict and minimise these stresses.

- Tempering the weld and HAZ microstructure. The microstructure,

particularly in the HAZ, can be hardened by rapid cooling of the weld.

This is a major problem for low and medium alloy steels containing chrome

and any other constituent that slow the austenite/ferrite transformation

down, as this will result in hardening of the micro structure, even at slow

cooling rates.

The risk of brittle fracture can be assessed by fracture mechanics.

Assuming worst-case scenarios for all the relevant variables. It is

then possible to predict if PWHT is required to make the fabrication safe.

However, the analysis requires accurate measurement of HAZ toughness, which

is not easy because of the HAZ’s small size and varying properties.

Some approximation is possible from impact tests, providing the notch is

taken from the point of lowest toughness.

If PWHT is to be avoided, stress concentration effects such as: - backing

bars, partial penetration welds, and internal defects in the weld and poor

surface profile, should be avoided. Good surface and volumetric NDT

is essential. Preheat may still be required to avoid hydrogen cracking

and a post weld hydrogen release may also be beneficial in this respect (holding

the fabrication at a temperature of around 250C for at least 2 hours, immediately

after welding).

Nickel based consumables can often reduce or remove the need for preheat,

but their effect on the parent metal HAZ will be no different from that created

by any other consumable, except that the HAZ may be slightly narrower.

However, nickel based welds, like most austenitic steels, can make ultrasonic

inspection very difficult.

Further reduction in the risk of brittle fracture can be achieved by refining

the HAZ microstructure using special temper bead welding techniques.

|

|

|